11 Tips for Successfully 3D Printing with ABS, ASA, and PC

If you want parts that are stronger and handle heat better than PLA, you'll probably look at ABS, ASA, and Polycarbonate. These filaments are trickier to print than PLA. They need more careful setup and patience, plus you have to understand how they behave. It's more work, but you can make parts that actually work in tough situations. The main thing to remember is that controlling your printing environment matters more than anything else with these materials.

Tip #1: Equip Your Printer with a High-Temperature, All-Metal Hotend

A lot of basic 3D printers have a PTFE tube inside the hotend. When temps rise above about 240°C, this tube can begin to break down. This can release harmful fumes and cause it to clog up more often. This happens a lot when people try to print at the higher temperatures needed for ABS, ASA, and especially PC.

You will need to get an all-metal hotend to successfully print these materials. The PTFE liner is taken out of the heated zone by this type of hotend, so it can safely hit the 270°C needed for ABS/ASA and the 300°C or higher that Polycarbonate often needs. This update makes sure that the temperature stays stable and is safe so that results are always the same.

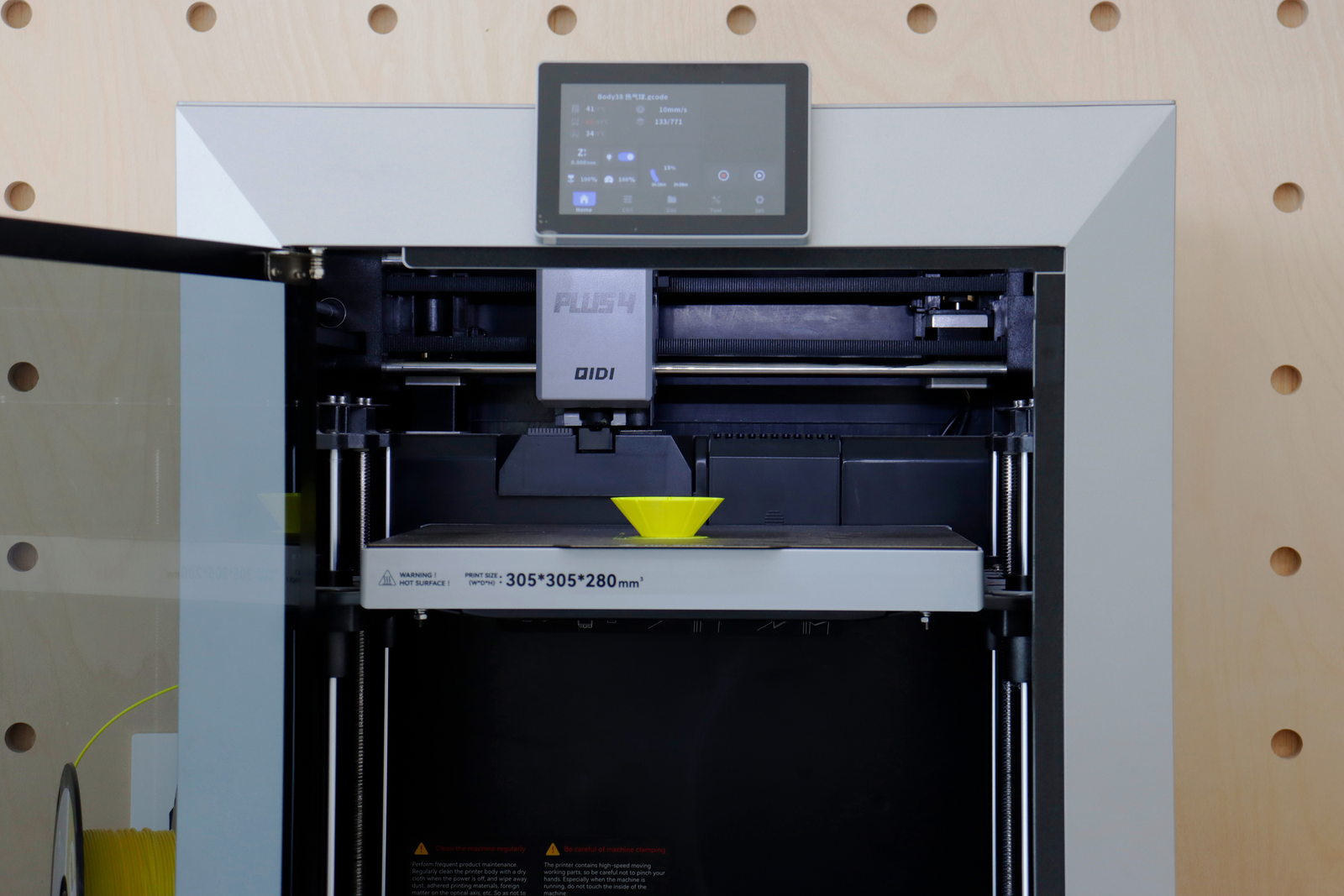

Tip #2: An Enclosure is Non-Negotiable

ABS, ASA, and PC all tend to shrink as they cool. If this cooling happens too quickly or unevenly, the print can warp, with corners lifting off the bed, or layers can split apart, which is known as delamination. An enclosure is the most effective way to prevent these issues. It traps heat from the printer's bed, creating a stable and warm environment around the print. This slows down the cooling process and reduces internal stresses.Understanding the fundamental reasons why use a 3D printer enclosure can further clarify its critical role in achieving these stable printing conditions.

- For ABS/ASA: A simple box, whether bought or homemade (from materials like acrylic sheets), is usually enough. It traps enough heat to prevent most warping and cracking.

- For Polycarbonate (PC): PC benefits greatly from a hotter, more controlled environment. For the best results, especially with larger parts, an actively heated chamber that can maintain a consistent temperature between 50-70°C is ideal. This helps ensure parts have good mechanical properties and minimal warping.

Tip #3: Select the Right Bed Surface and Keep it Hot

Good first-layer adhesion is critical. These advanced materials need a hot print bed to prevent the base of the model from cooling too fast, shrinking, and detaching.

- Bed temperatures are typically 100-110°C for ABS and ASA.

- Polycarbonate usually requires even higher bed temperatures, often between 110-130°C.

The type of build surface is also important. While some people use glass with adhesives, other surfaces can offer more reliable adhesion.

- PEI (Polyetherimide) sheets: PEI sheets are a popular choice, available in smooth or textured finishes. They provide good adhesion when hot and parts often release easily once cooled.

- Garolite (G-10) sheets: These offer excellent adhesion and durability, making them suitable for engineering-grade filaments.

Tip #4: Keep Your Filament Bone-Dry

Many high-performance filaments are hygroscopic, meaning they absorb moisture from the air. Polycarbonate is particularly prone to this, while ABS and ASA are also affected. If the filament is "wet," the moisture turns to steam in the hotend, creating bubbles in the extruded plastic. This results in weak, brittle prints with a poor surface finish and increased stringing, damaging the print quality.

It's crucial to dry your filament before printing. A dedicated filament dryer is a worthwhile investment.

- Drying Guidelines: Typically, dry ABS/ASA at around 65°C and PC at 70-80°C for at least 4-6 hours.

- Best Practice: For very sensitive materials like PC, printing directly from the filament dryer can help ensure it stays dry throughout the printing process.

Tip #5: Tame Warping with Brims and Rafts

Even with the controlled environment provided by an enclosure and a heated bed, parts with sharp corners or small areas of contact with the bed can still lift. Slicer settings like brims and rafts can help.

- Brim: A brim adds several lines of filament around the base of your model, increasing its contact area with the bed. This helps hold down the edges. A brim of 10-20 lines is a good starting point for most parts.

- Raft: For parts very prone to warping, like long, thin objects, a raft provides a more robust solution. A raft is a thick base of filament printed first, and the model is then printed on top of it. This gives the model a stable foundation.

Tip #6: Use a Temperature Tower to Dial In Settings

Filament manufacturers provide recommended temperature ranges, but the optimal temperature can vary between brands and even colors. Printing a temperature tower model helps you find the best extrusion temperature for each new spool. This model prints sections at different temperatures, allowing you to check for layer adhesion, surface quality, and stringing. You're generally looking for the highest temperature that gives a strong part with a clean surface.

Starting Ranges: For ABS/ASA, try a range of 240-260°C. For Polycarbonate, start between 270-310°C.

Tip #7: Master the Cooling Fan (Hint: Turn it Off)

When you print PLA, you know how important the part cooling fan is. For ABS, ASA, and PC, on the other hand, the part cooling fan can often go wrong. Rapid cooling from the fan can cause temperature drops in certain areas, which can cause layers to separate and parts to become weaker.

If you want to print most of these materials, set the part cooling fan to 0% for the whole print. Setting up the enclosure as we talked about in Tip #2 and letting it cool slowly and evenly is what helps make strong layer ties. This rule is mostly broken for models with huge overhangs or very short layer times, which need extra help to harden quickly. Sometimes, a very slow fan speed (10–25%) is used, but it's better not to use it.

Tip #8: Slow Down for Better Layer Adhesion

Most of the time, people want faster printing, but for these engineering products, the quality of the print and its strength are more important. At print speeds between 30 and 60 mm/s, each layer has more time to melt properly and join with the layer below it. This makes the connection between layers stronger and the part stronger all around.

Tip #9: Let It Cool Down Slowly

It can be tempting to remove a print as soon as it's finished, but this can cause it to warp. If a hot part is suddenly exposed to cooler room air, it can experience thermal shock. After the print finishes, turn off the printer's heaters but keep the enclosure closed. Allow the part and the bed to cool down to room temperature gradually. Parts will often detach on their own as they cool.

Tip #10: Handle Fumes Responsibly

Safety is important. When printing ABS and ASA, styrene (a VOC) is released, which has a strong odor and can be irritating.

- Best Option: Vent the fumes from the printer enclosure directly outside using a fan and ducting.

- Good Alternative: Use an activated carbon and HEPA filter (like a BentoBox or similar designs) inside the enclosure to filter the air.

- Minimum: Ensure the room has very good ventilation.

Tip #11: Consider Post-Print Annealing for Maximum Strength

For parts that need maximum strength and heat resistance, annealing can be beneficial. This heat treatment process helps relieve internal stresses created during printing. To anneal a part, place it in a convection oven on a bed of sand (to support it and prevent sagging) and heat it to just below its glass transition temperature for about an hour. Then, let it cool slowly in the oven. This can significantly improve the part's mechanical properties. Always research the specific annealing temperature for your filament brand.

Material-Specific Tips: Nuances Matter

While these general tips apply to all three materials, each has its own unique personality that requires a slightly different approach.

For ABS

This is often the first advanced material people try. It is the most forgiving of the three regarding bed adhesion on a PEI sheet but also produces the most noticeable odor. For ultimate adhesion, especially on a glass bed, some users create an "ABS slurry" by dissolving scrap pieces of ABS filament in acetone and brushing a thin layer onto the build plate.

For ASA

Think of ASA as a modernized version of ABS. It is slightly less prone to warping and generally easier to print. Its key advantage is superior UV resistance, which means it will not become brittle or yellow when exposed to sunlight over long periods. This makes it the ideal choice for any functional parts that will be used outdoors.

For PC

Polycarbonate exists in another league of difficulty and is not recommended for beginners. This material is unforgiving of mistakes. The single most important rule is to keep the filament perfectly dry; do not ever skip the drying step. You must print it in the hottest, most stable environment you can create, making an actively heated chamber highly recommended. If a PEI sheet is not providing sufficient adhesion, a specialized adhesive like Magigoo PC is often necessary to lock the first layer in place.

Print Advanced Filaments Successfully!

Printing with ABS, ASA, and Polycarbonate requires more setup than PLA, but the results justify the effort. You need proper equipment—an all-metal hotend, enclosure, and heated bed—plus careful attention to filament storage and environmental control. While the learning curve is steeper and safety matters, these materials let you create functional parts that handle real stress, heat, and outdoor conditions. This shift from hobby printing to engineering-grade materials transforms your printer into a tool for solving actual problems.